Tel:189-1186-2450

Mobile:189-1186-2450

Email:njzzcg888@163.com

Address:7th Floor, R&D Building, Building 51, Emerging Industries, Nanjing University Science Park, No. 8 Yuanhua Road, Xianlin Street, Qixia District, Nanjing City; Beijing Office: No.1 Zhongliang Road, Daxing District, Beijing, Zhuzong Vanke Plaza

High measurement accuracy, fast response speed, intrinsic safety, explosion-proof, and anti electromagnetic interference

Fiber Bragg Grating Surface Strain Gauge

Model:ZZ-FBG-SE3000

1、Summary

The Nanjing Zhunzhi ZZ-FBG-SE3000 fiber optic grating surface strain gauge is mainly used to measure the strain of metal structures, piles, bridges, buildings, etc. The difference between Type A and Type B is that Type A has a built-in reference grating in addition to a strain measuring grating, which can perform one-on-one temperature compensation; Type B only has one strain measuring grating, and temperature compensation requires an external thermometer. If multiple sensors are placed in the same temperature environment, a shared temperature compensation method can be used to save channels and costs。

Our company also provides a high tensile strength grating that can replace ordinary gratings:

There are two main technical schemes for using femtosecond laser pulses to induce refractive index changes in the fiber core to write fiber Bragg gratings: one is the point by point etching method, which uses a focused femtosecond laser beam to expose along the fiber point by point, forming a periodic distribution of the refractive index of the fiber core and making fiber Bragg gratings; The second is the phase mask method, which is similar in principle to traditional phase mask methods, except that the exposure light source is improved by femtosecond pulse laser. The new femtosecond laser point by point direct writing technology efficiently and flexibly manufactures high-end FBG - fsFBG. Its advantage lies in: writing FBG directly on the fiber specified or provided by the user; The nonlinear optical effect of femtosecond laser generates extremely stable and indelible gratings as sensor devices; Extreme stability up to 1000 degrees Celsius; By directly writing through the coating layer, the better mechanical strength of the fiber is retained, and the excellent performance of the special coating layer is retained, which is much higher than the mechanical strength of the conventional peeling and recoating method of fiber Bragg gratings; Anti radiation, anti moisture, anti hydrogen darkening, anti electromagnetic interference。

Polyimide is a new type of high-temperature resistant material with extremely high heat resistance, excellent chemical stability, good electrical insulation, and high mechanical strength. It is a polymer material with the highest heat resistance level that has been widely used in the aerospace, electrical, and microelectronics industries. In order to ensure that the coating layer will not be burned out at a welding temperature of 270 ℃ for low melting point glass, the present invention selects a polyimide coated optical fiber。

Low melting point glass is a type of low-temperature sealing glass solder. In the packaging process, the metal tube sleeve can be directly sealed with the optical fiber without the need to metallize the surface of the optical fiber. It has good wettability and can achieve airtight packaging; Good chemical stability, no gas is generated during the sealing process, and there is no residue after sealing; The airtight sealing temperature is relatively low, with a sealing temperature range of 270 ℃~380 ℃, making it easy to operate; Strong applicability, compared to traditional packaging, the components packaged with this product have a longer lifespan. Compared to conventional epoxy resin encapsulation processes, fiber optic gratings rely on low melting point glass welding, which provides good contact point stability and eliminates wavelength zero drift caused by creep。

Fiber optic gratings coated with polyimide, combined with low melting point glass welding technology, are directly welded to metal elastomers at both ends of the grating. The elastomers are then placed on a base and protected with protective tubes。

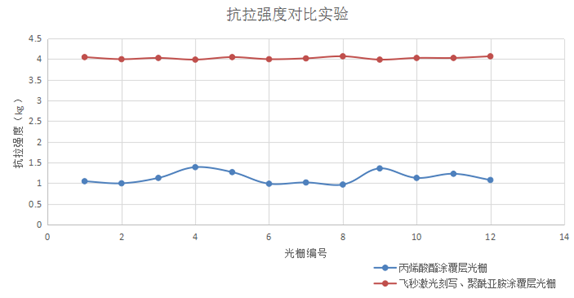

The comparison of the tensile strength of mechanical sensors for fiber grating structures packaged with ordinary acrylic coated fiber Bragg gratings and femtosecond laser direct writing polyimide fiber Bragg gratings is shown in the figure

The core structure of ZZ-FBG-SE3000 adopts a high elastic metal structure, which encapsulates two series connected fiber Bragg gratings inside the structure, one for strain measurement and the other for temperature compensation. During measurement, the sensor receives stretching and compression deformation, which drives the internal strain grating to stretch and compress, causing a change in the reflection wavelength. The change in the reflection wavelength is detected by the background demodulator to achieve the measurement purpose。

This sensor is suitable for strain monitoring on various environmental surfaces. During installation, the mounting base needs to be fixed on the tested structure. The installation method can be selected based on the material of the tested structure or the allowed environment on site. The surface can be welded or expanded with screws。

2、Performance Parameter

Project | Company | Reference Value |

Standard range | με | Femtosecond grating sensor:-2500~+2500 Ordinary grating sensor:-1500~+1500 |

Accuracy | με | 0.5%F·S |

Resolving Power | με | 1με (Femtosecond grating sensor:0.02%FS Ordinary grating sensor:0.033%FS) |

Sensor gauge length | mm | 150(Customizable) |

Center wavelength of grating | nm | 1525~1565 |

Working temperature range | ℃ | -30℃~+80℃ |

Number of single channel sensors | branch | 5 |

Sensor lead out and connectors | FC/APC, Double ended armored optical cable with a length of 1m and a diameter of 3mm/6mm | |

Connection method between sensing heads | Series connection/flange connection/optical cable fusion | |

Overload capacity | 1.15x | |

Temperature compensation method | Reference grating: A-type built-in temperature compensation, B-type external temperature compensation | |

Installation method | Welding, bolt fixation, pasting |

189-1186-2450

189-1186-2450

7th Floor, R&D Building, Building 51, Emerging Industries, Nanjing University Science Park, No. 8 Yuanhua Road, Xianlin Street, Qixia District, Nanjing City; Beijing Office: No.1 Zhongliang Road, Daxing District, Beijing, Zhuzong Vanke Plaza

7th Floor, R&D Building, Building 51, Emerging Industries, Nanjing University Science Park, No. 8 Yuanhua Road, Xianlin Street, Qixia District, Nanjing City; Beijing Office: No.1 Zhongliang Road, Daxing District, Beijing, Zhuzong Vanke Plaza

Copyright© All Rights Reserved for Intelligent Sensing SuICPB No. 2024111040 技术支持:中企云达